Different blister card filling methods exist: manual, semi-automated, automated and outsourced to a central fill. But what are the differences between them, and how can you choose a method that suits your pharmacy’s needs?

In pharmacies, blister cards can be filled in different ways, depending on the processes and equipment available.

An operator manually places the drugs in the blisters of the card. This method is often used for small production volumes, for drugs requiring delicate handling or specific storage.

The use of a semi-automated system facilitates the filling process and reduces the risk of error. An operator manually positions the drugs in the blisters, but is assisted by a guidance system. This mode is used to ensure the safe production of small volumes, drugs requiring delicate handling or specific storage.

This mode uses automated systems to fill blister cards. The drugs are stored in the system, which then selects and dispenses the required drugs as per the prescriptions sent. This filling mode is commonly used for higher production volumes, enabling blister cards to be filled quickly and accurately.

Delegating the production of blister cards to a Central Fill is another convenient option. A Central Fill pharmacy is an efficiently run production site that sends completed cards back to the dispensing pharmacy. Like automated filling, this option is commonly used for higher production volumes and removes the labour component from the dispensing sites.

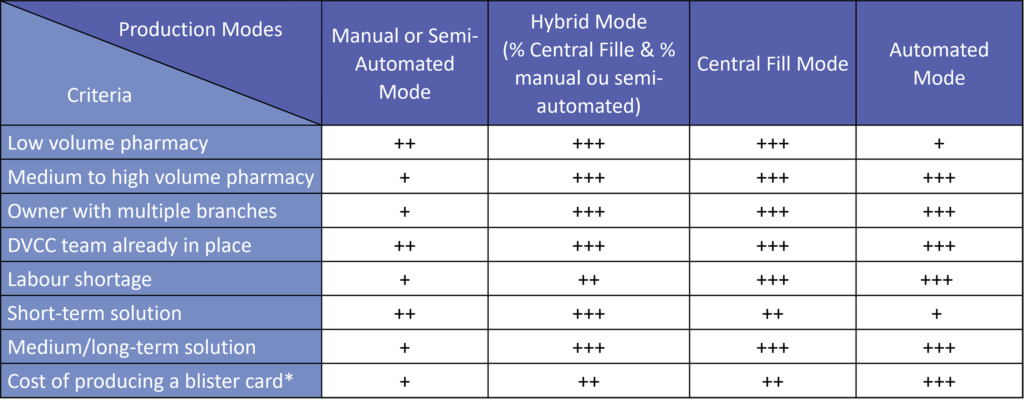

When choosing how to fill blister cards in pharmacies, a number of factors need to be taken into account to ensure optimum efficiency and quality of the process. Here are a few important points to consider:

The planned production volume is a key factor in the choice of a filling method. For small production volumes, manual or semi-automated filling may be sufficient, whereas for large volumes, automated filling or outsourcing production to a Central Fill is generally more appropriate, to ensure higher productivity and profitability.

Some drugs are more delicate than others and require specific handling when filling blister cards. For example, drugs that are sensitive to humidity or light may require a more controlled filling process or special conditions to maintain their stability. It is important to take into account the specific characteristics of the drugs to be dispensed.

The time available for filling blister cards can be a determining factor. Automated filling methods are generally faster and can process large quantities of drugs in a short time, whereas manual or semi-automated filling methods can be more time-consuming and labour-intensive. Also, automation allows for better planning and production closer to the patient delivery date.

It is important to assess the costs associated with each filling method, including initial investment in equipment, maintenance costs, staff training requirements and available human resources. It is essential to choose a filling method that is economically viable and suited to the resources available.

By carefully evaluating these factors, pharmacists can choose the blister card filling method that best meets their specific needs in terms of volume, type of drugs, accuracy, time, costs and resources.

* Equipment and maintenance costs are excluded from the calculation.

Legend:

+ Non-Optimal Solution

+++ Optimal Solution

Victory House

400 Pavilion Drive

Northampton, UK

NN4 7PA

Telephone : England, Scotland & Wales : 0203 903 6318 – Option 1

Northern Ireland & Eire : 0800 700 10 701 – Option 1

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |